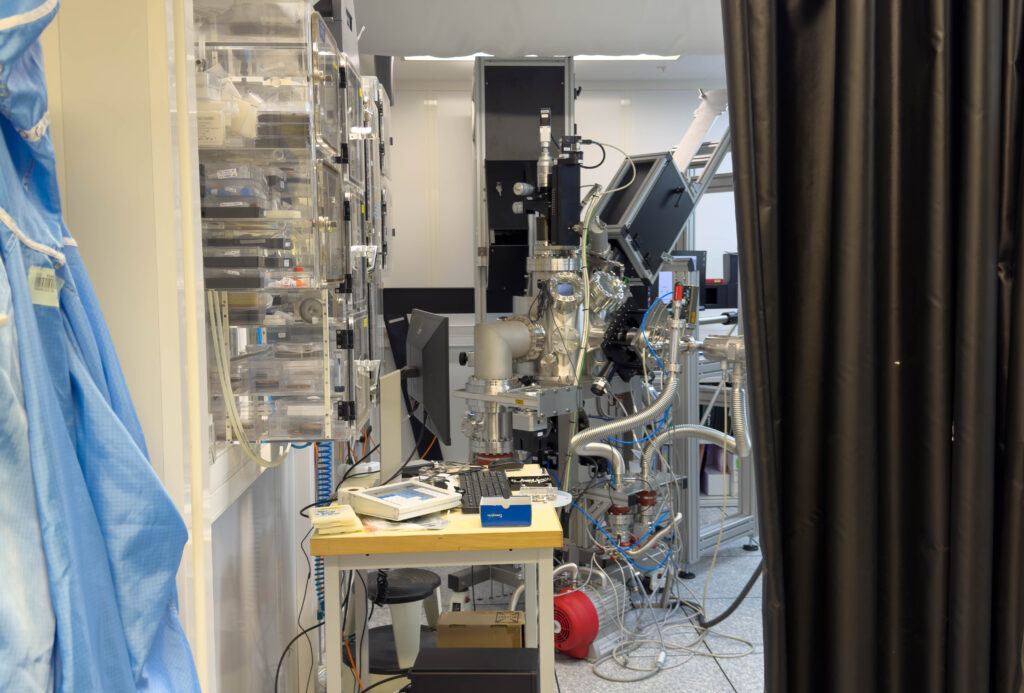

The Albert Fert Laboratory Receives Its New Pulsed Laser Deposition (PLD) System

The Laboratoire Albert Fert has recently acquired a new Pulsed Laser Deposition (PLD) system, a state-of-the-art installation dedicated to the fabrication of functional thin films. Now fully operational, this equipment paves the way for the rapid development of new complex materials and the advancement of innovative processes within the framework of the PEPR SPIN program

The Pulsed Laser Deposition (PLD) technique has emerged as one of the most versatile methods for the fabrication of ultra-thin functional layers. Widely used in both fundamental research and applied R&D, it accelerates the development of novel complex materials. PLD also plays a key role in technology transfer toward industrial processes with high potential returns, including for demanding materials such as garnets or high-temperature superconductors.

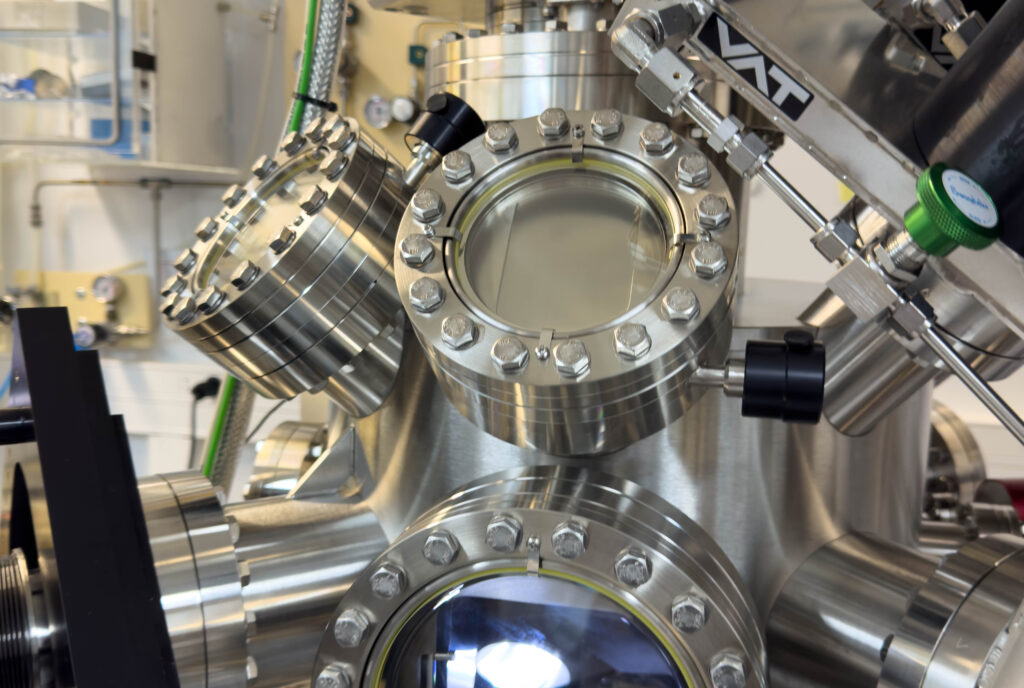

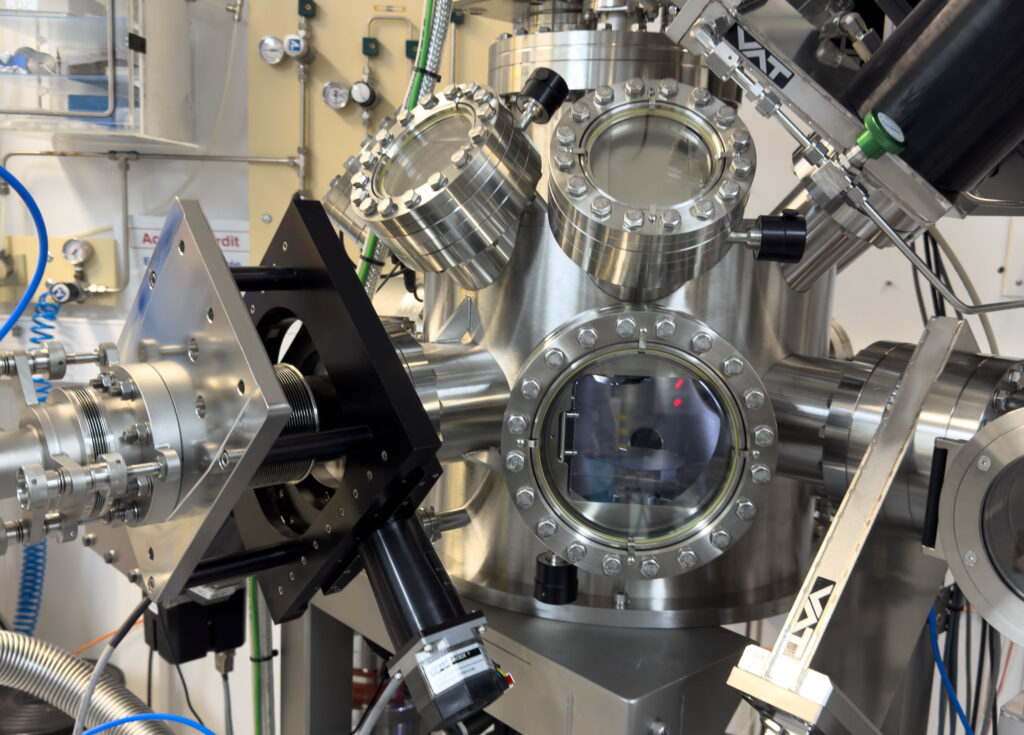

A High-Precision Deposition Method

The process consists of depositing thin films under a controlled atmosphere using a high-energy, short-wavelength pulsed laser beam to ablate a dense target containing the elements of the desired material. The ejected species, highly energetic, are then slowed down by an ambient gas—most commonly oxygen—before condensing onto a heated substrate, forming a thin layer that faithfully reproduces the composition of the target.

Complementary Laser Sources

Most PLD systems use either a gas laser emitting at 248 nm or a solid-state laser emitting at 355 nm. The optimal laser choice depends closely on the target material and remains difficult to predict. However, gas lasers rely on fragile supply chains, which have been further weakened by recent geopolitical tensions.

A New Generation of Hybrid Systems

As part of the PEPR SPIN program, a hybrid PLD system has been developed, capable of operating with either type of laser. This technological flexibility helps reduce strategic dependence on critical materials while broadening the scope of scientific research conducted on the platform. It thus strengthens scientific and technological sovereignty and supports innovation in the field of advanced materials.

We would like to thank Demcom TSST for its support and for providing this equipment, thereby supporting the implementation of our SPIN Research Program.