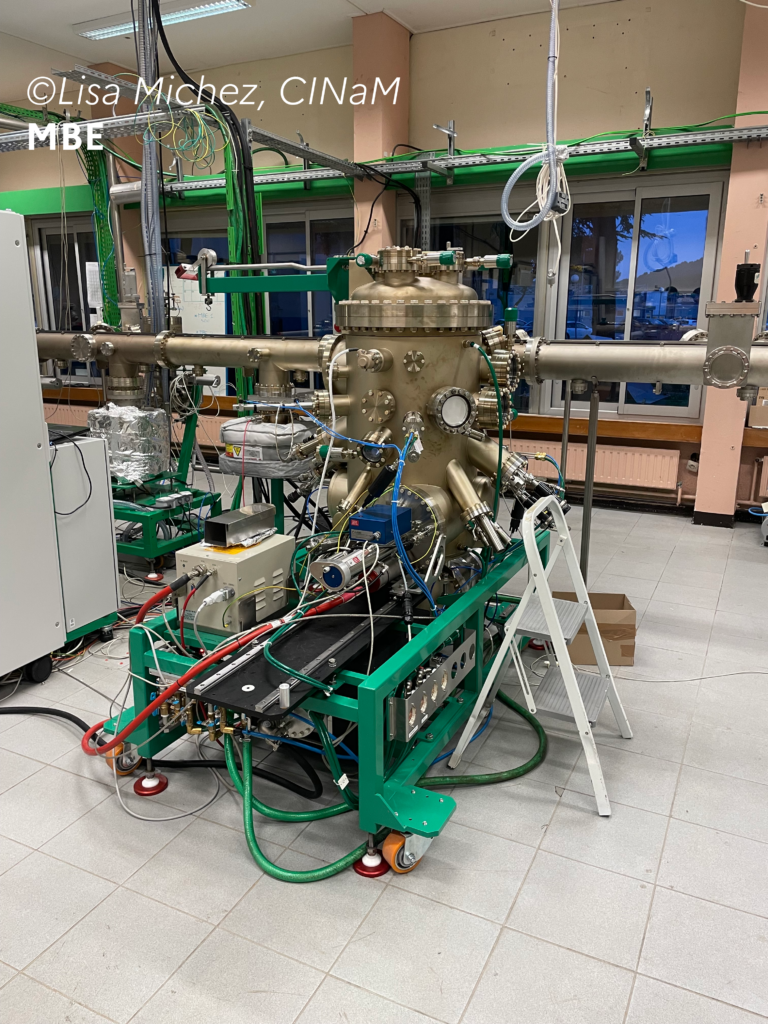

A new molecular beam epitaxy chamber at CINaM

CINaM (CNRS|Aix-Marseille Université) is equipping itself with a state-of-the-art molecular beam epitaxy (MBE) chamber, featuring a 6-pocket electron beam evaporator. This equipment, funded by the SPIN Research Program, will pave the way for the growth of complex materials and heterostructures, which are essential for advancements in spintronics and materials physics

Context: Molecular beam epitaxy (MBE):

Molecular beam epitaxy (MBE) is a thin-film growth technique based on the thermal evaporation of materials in an ultra-high vacuum environment (pressure < 5 x 10⁻¹⁰ mBar). The generated vapor flux condenses on a substrate surface, enabling the formation of thin films. Due to the low energy of the incident atoms (~100 meV), the process is governed by thermodynamic principles, where surface energies, diffusion, and elastic strain play a central role.

MBE is widely recognized as one of the most precise methods for achieving single-crystalline films with near-atomic resolution. While historically developed in the 1970s for semiconductor growth (e.g., Si, Ge, GaAs), it is now applied to a broad range of materials, including oxides, metals, nitrides, and organic compounds.

Objectives:

The Spintronics & Epitaxy Group at CINaM, deeply involved in the SPINMAT axis of the SPIN Research Program, focuses on the growth of innovative magnetic compounds, such as the altermagnet Mn₅Si₃ and the chiral antiferromagnet Mn₃Sn. The arrival of this new MBE chamber will enable the development of fully epitaxial heterostructures, which are essential for:

> The discovery of novel compounds.

> Spin-to-charge current conversion,

> Superconducting proximity effects,

> Magnetic tunnel junctions,

Technical characteristics:

The CINaM’s MBE chamber stands out with the following features:

A high-temperature manipulator: Capable of maintaining sample temperatures up to 1200 °C, ideal for synthesizing demanding materials.

> A 6-pocket electron beam (e-beam) evaporator: Expands the team’s capabilities by enabling the evaporation of low-vapor-pressure metals (Pt, Co, Ir), insulating barriers (MgO, MgOAlx), and semiconductors (Si, Ge)—materials that cannot be processed using standard effusion cells.

> An in-situ electron diffraction gun: Allows real-time monitoring of film growth.

This MBE chamber opens unprecedented opportunities for spintronics research, combining atomic precision with material flexibility. It positions CINaM as a key player in the exploration of novel compounds and devices, addressing the technological challenges of tomorrow.

The SPIN Research Program extends its gratitude to the teams at Vinci Technologies for their support throughout this process and during its installation.